Ducted Fume Hood

What is Ducted Fume Hood?

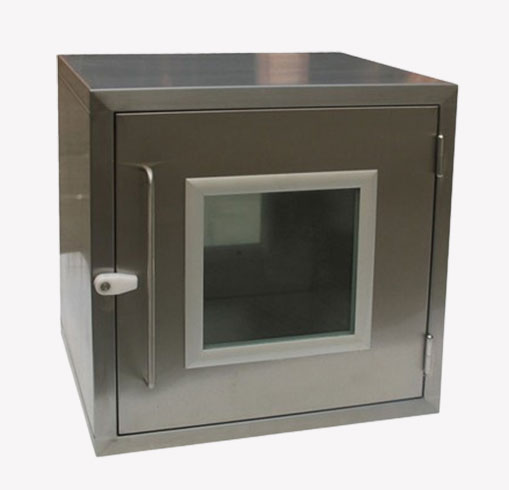

A Ducted Fume Hood is a ventilation system that is commonly used in laboratory settings to protect workers from harmful gases and airborne contaminants. The hood is designed to capture and remove fumes, vapors, and other hazardous materials from the air, and direct them outside through a duct system. The hood is typically made of stainless steel and features a sash or shield that can be opened or closed to control the airflow. Ducted Fume Hoods are an important safety measure in laboratory environments, as they help to ensure that workers are not exposed to harmful substances that could cause injury or illness.

How Ducted Fume Hood Works?

The working principle of a Ducted Fume Hood involves containment, airflow, and filtration mechanisms. It is designed as an enclosed workspace with a transparent front sash or door, preventing direct exposure to hazardous substances while allowing visibility and access to the equipment inside. The hood operates on controlled airflow principles, with an exhaust system connected to ductwork that removes contaminated air from the hood’s interior.

An exhaust fan creates negative pressure inside the hood, drawing air and contaminants towards it. To maintain balance and prevent the creation of a vacuum, a supply air system provides fresh air into the hood, creating a slight positive pressure that directs airflow from the hood’s interior to the surrounding area, preventing the escape of hazardous substances. Many Ducted Fume Hoods incorporate filters to enhance safety and environmental protection, including activated carbon filters for removing volatile organic compounds (VOCs) and specific chemical filters for capturing toxic gases. Modern hoods come equipped with sensors and controls to monitor airflow, face velocity, and filter saturation, ensuring optimal functioning and alerting users when maintenance or filter replacement is necessary.

Benefit of Ducted Fume Hood

Ducted Fume Hoods offer several benefits in hazardous chemical handling processes. They provide a controlled and enclosed workspace, ensuring that hazardous fumes, vapors, and particles generated during chemical processes are contained within the hood, protecting the user and the surrounding environment from exposure to harmful substances. By effectively containing and removing hazardous substances, they significantly contribute to the safety of laboratory personnel and workers, minimizing the risk of inhalation or skin contact with toxic chemicals. They maintain air quality in the laboratory or workspace by continuously removing and filtering contaminated air, preventing its dispersion into the surrounding area and maintaining a healthy working environment.

Ducted Fume Hoods assist in meeting regulatory compliance requirements for handling hazardous substances, providing an effective engineering control measure for the containment and removal of harmful chemicals, ensuring safety, and avoiding potential legal and financial consequences. They can be customized to suit specific laboratory needs and processes, accommodating various sizes and types of equipment, and incorporating different types of filters for the removal of specific chemical compounds. Modern hoods come equipped with monitoring systems that provide real-time feedback on performance and alert users to maintenance needs, enhancing safety and ensuring optimal operation.

Application of Ducted Fume Hood

Ducted Fume Hoods have a wide range of applications across various industries and settings where the handling of hazardous substances is involved. Here are some common applications:

Laboratories

Ducted Fume Hoods are extensively used in chemical, pharmaceutical, and research laboratories. They provide a safe environment for conducting experiments, handling volatile chemicals, and containing potentially harmful fumes and vapors.

Industrial Manufacturing

Industries dealing with chemicals, solvents, and toxic materials utilize Ducted Fume Hoods to safeguard workers and maintain air quality. These hoods provide a controlled ventilation system for processes such as mixing, blending, and handling hazardous substances.

Educational Institutions

Schools, colleges, and universities with science laboratories employ Ducted Fume Hoods to ensure the safety of students and instructors. They enable practical demonstrations, experiments, and research involving chemicals, acids, and other potentially harmful materials.

Healthcare Facilities

Ducted Fume Hoods find applications in healthcare settings, particularly in pharmacies and research facilities. They aid in the preparation of pharmaceutical compounds and ensure the containment of volatile substances and potentially harmful drug residues.

Chemical Manufacturing

Industries engaged in chemical production and synthesis utilize Ducted Fume Hoods to mitigate risks associated with handling toxic chemicals, preventing their release into the environment, and protecting workers from exposure.

Quality Control and Testing Laboratories

Testing laboratories, including those involved in environmental analysis, food safety, and product quality control, use Ducted Fume Hoods to handle samples containing hazardous substances. This helps prevent cross-contamination and ensures accurate results.

Research and Development

Ducted Fume Hoods are crucial in research and development facilities across industries. They enable the safe handling of various chemicals, gases, and volatile compounds during the development of new products, processes, or technologies.

Flexibility in Workspace Design

Accommodates unique spatial requirements, providing flexibility in workspace layout, especially where side-to-side.

Contact Ducted Fume Hood Manufacturer

Ducted Fume Hoods create a safe and controlled environment by combining effective containment, controlled airflow, and filtration systems for handling hazardous substances. They play a important role in maintaining a safe working environment, protecting workers, and preventing the release of hazardous substances into the surroundings across a wide range of industries and applications. Their containment, ventilation, and filtration capabilities provide a reliable and effective means of reducing exposure risks and creating a safer working environment.