Dynamic Pass Box

Dynamic Pass Box Manufacturer

We are one of the leading Dynamic Pass Box manufacturer and supplier in UAE, Dubai. Our wide range of clean room equipment such as Laminar Air Flow, Pass Box, Fume Hood, Clean Room Furniture and Lab Accessories are also available in various countries like UAE, Africa, Oman, Saudi Arabia, Qatar, Oman, Yemen, Sudan, Bahrain and many others. Our these products are perfect for various R&D, Pharmaceuticals, Electronic Industries, Food Processing, Chemical, Laboratories, Clinics in various applications. These pass boxes are not only made from quality materials but also tested on various parameters to ensure its reliability and efficiency.

Feel free to get in touch!

info@labswas.com

+91 97262 18377

Feel free to get in touch!

info@labswas.com

+91 97262 18377

Dynamic Pass Box Definition

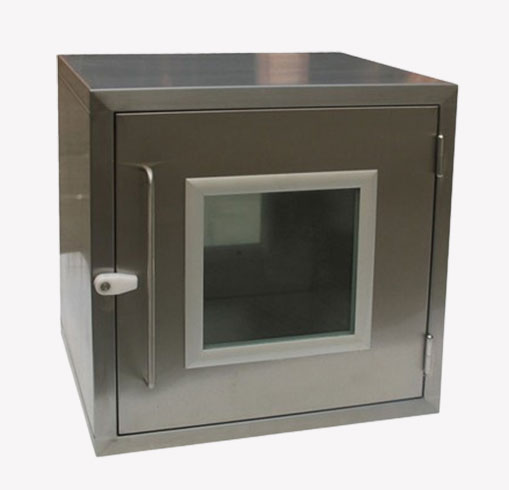

A dynamic pass box is a special piece of equipment that is used in clean rooms and controlled environments to safely transfer materials. These materials are transferred from one room to another of different cleanliness levels. Indeed, this box helps to prevent contamination and maintain the cleanliness standards of the room. It is not like static pass boxes. This is because dynamic pass uses an air circulation system to actively filter and purify the air during the transfer process. Dynamic pass boxes are completely made of stainless steel for maximum durability. Due to the steel construction, such boxes prevent particle accumulation. They also feature HEPA or ULPA filters, which remove contaminants from the air effectively. Since the boxes are equipped with interlocking doors, they ensure that both doors cannot be opened simultaneously. This reduces the risk of contamination. Note that the application of static devices is common in pharmaceuticals, biotechnology, electronics, and research labs.

What is Dynamic Pass Box?

Dynamic pass box helps to transfer materials safely from one room to another with different levels. It is due to their inbuilt air filtration system, which helps to maintain positive pressure inside the box. These boxes also have a unique UV light, which helps in standardizing the space inside the box. These boxes are indispensable in industries where maintaining cleanliness and sterility is non-negotiable. They ensure contamination-free material transfer and also enhance operational efficiency. Moreover, they help to comply with industry standards. Operators keep the pressure difference for a dynamic pass box based on the standards and type of clean room. Generally, the pressure difference is 10 to 15Pa. It means that the air pressure inside the pass box should be 10 to 15 Pa higher than the outside.

Dynamic Pass Box Uses

There are various uses of dynamic pass boxes in different industries where cleanliness is the first priority. Pharmaceuticals use dynamic pass boxes extensively to transfer raw materials, samples, and finished products between different clean rooms. These clean rooms have unique classifications like goods transfer from grade C to grade A. Since they have advanced filtration systems, they ensure that sensitive pharmaceutical products remain safe and untouched. Additionally, dynamic pass boxes are the top favorite of biotechnology labs. These labs use boxes to facilitate the movement of biological samples and reagents in a controlled atmosphere. They transfer materials between cleanrooms, laboratories, and other controlled environments, preventing cross-contamination. This is very important to maintain the integrity of the samples. These boxes work great for sensitive experiments.

Moreover, the electronics industry employs dynamic pass boxes to transfer components that are sensitive to dust and particulate matter. These boxes help protect delicate electronic parts from contamination during the assembly and testing process. Not to forget, the food processing department also uses dynamic pass boxes to transfer food ingredients and packaging materials while adhering to strict hygiene standards. Raw and processed food items are prone to cross-contamination, but pass boxes prevent the situation. There are some research settings that involve microbiology or chemical analysis. They allow for safe material transfers without compromising experimental results.

Benefits of Dynamic Pass Box

Dynamic Pass Boxes offer several benefits in industries where cleanliness and contamination control are crucial. They provide a controlled environment for material transfer, ensuring no contaminants are introduced during the process by maintaining positive pressure and using HEPA filters. The double-door system with interlocking mechanisms prevents cross-contamination by ensuring no direct airflow exchange between different cleanliness zones. They enhance cleanroom efficiency by streamlining the transfer process, saving time, minimizing disruptions, and reducing human error. Compliance with regulatory standards is ensured by providing a reliable method for material transfer.

Dynamic Pass Box Working Principle

A dynamic pass box enables the safe transfer of materials between different areas such as from non-clean zones to clean rooms. It does not require personnel to enter the clean room. The dynamic pass box consists of a compact enclosure with two interlocked doors. Note that these doors have a unique design so that only one can open at a time. This ensures no direct contact takes place between the two areas. When the operator places materials inside the pass box and closes the first door, the system activates its fan or blower unit. This fan draws air from the clean room and directs it through a HEPA or ULPA filter which removes 99.97% of particles of 0.3 µm. Therefore, the filter purifies the air effectively. The filtered air then blows into the past and creates positive pressure. This pressure keeps contaminants from entering the enclosure from outside. The operator can then open the second door to transfer the material into the clean room.

Additionally, the positive pressure and filtered air ensure that the material remains free of contaminants during the transfer. Once the transfer is complete, the operator closes the second door. The system continues to circulate clean air for a fixed duration to remove any potential contaminant. After this cycle, the fan switches off. Besides, the pass box is ready for the next use.

Dynamic Pass Box Specification

| Model | SEDP150 | SEDP200 | SEDP300 |

|---|---|---|---|

| Design type | Dynamic | Dynamic | Dynamic |

| Cleanliness level | Class 100 | Class 100 | Class 100 |

| Internal Dimension (in mm) | 450L x 450W x 450H | 610L x 610W x 610H | 910L x 910W x 910H |

| Outer Dimension (in mm) | 570L x 510W x 950H | 730L x 670W x 1100H | 1030L x 970W x 1410H |

| MOC | Stainless steel 304 | ||

| Illumination | LED tube light | ||

| Air system | Motor-blower with suspension arrangement | ||

| Filters | Pre filter (95% down to 5 micron) HEPA filter (99.97%) Protected by SS grills | ||

| Door | Two side doors Glass windowSS handles & SS hingesElectromagnetic Interlocking system | ||

| Standard Fittings | UV light Light indicators for doorSS Handles & SS hingesOn / Off Switch for blower | ||

| Power supply | 220 Volts / 50 Hz | ||

| Optional | MOC SS 316 / 316 L Differential Pressure Gauge DOP Test Port Flange Test certificates Calibration certificate Mechanical door interlocking Door buzzer/UV light hour meter | ||

Contact Dynamic Pass Box Manufacturer

Searching for a best Dynamic Pass Box manufacturer in UAE, Dubai? Then contact Labswas as we are the only clean room equipment manufacturing company working under all the necessary international norms and regulations. Our manufacturing plant is equipped with modern equipment to deliver best pass boxes in your laboratories. These equipment are made with premium materials and tested for its durability and performance under various circumstances. They provide best performance and require minimum maintenance. That is the reason they are highly appreciated among customers. Moreover, we also offer custom product solutions to fulfill your all application requirements. Our support team is always ready to fulfill client needs and user requirements. Contact us now to discuss your product requirements.