Fume Hood

Fume Hood Manufacturers

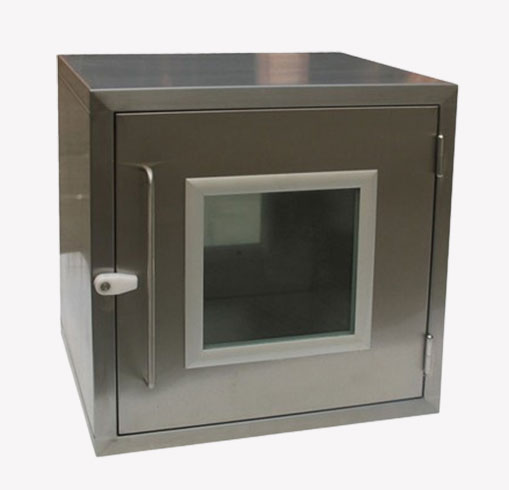

We are the leading Fume Hood manufacturers and suppliers in UAE, based in India. We have expertise to manufacture wide range of Fume Hood, Laboratory Fume Hood and Industrial Fume Hoods. A fume hood is also called a Fume Extraction Hood, Fume Hood Cabinet or Lab Fume Hood. It is a safety device with a closed cabinet that protects lab people from harmful films, vapor, and dust in lab settings. It works as an enclosed workspace with a movable sash window. Additionally, it traps and exhausts gases, either outside the building through a duct or back into the room using air filtration.

Feel free to get in touch!

info@labswas.com

+91 97262 18377

Feel free to get in touch!

info@labswas.com

+91 97262 18377

What is a Fume Hood?

A fume hood is important cleanroom equipment used in laboratories to protect workers from hazardous fuels, vapors, gas, and dust. These particles are produced during chemical experiments or processes. Therefore, hoods allow lab employees to safely work with potentially dangerous chemicals without exposure to toxic and harmful substances. We offer wide range of Fume Hoods such as Laboratory Fume Hood, Chemistry Lab Fume Hood, Industrial Fume Hood and many more.

How Does a Fume Hood Work?

A fume hood removes harmful gases, vapors, and fumes from a work area. An exhaust fan pulls air and contaminants through ducts and releases them outside. Most fume hoods have a movable front sash and interior baffles. The sash can move up and down or side to side, protecting the user by creating a barrier between them and the experiment. The baffles help direct the airflow, and they can be adjusted for the best performance. It’s important not to block the baffles with materials or equipment, as this can affect the airflow and the hood’s efficiency. The frame around the hood called the airfoil, helps air flow smoothly into the hood. It reduces turbulence.

It can be classified as given below:

- Constant Volume: The exhaust airflow stays the same. When the sash is lowered, the airflow speed increases to maintain effective capture.

- Variable Air Volume (VAV): The airflow changes automatically as the sash is raised or lowered to keep the airflow speed steady, reducing the total air volume exhausted.

Fume Hood Purpose

Purpose of the fume hood is to provide a safe workspace for handling harmful chemicals, biological agents, and radioactive materials. It protects users from inhaling toxic fumes or vapor that come from chemical reactions. Additionally, they maintain a constant flow of air and ventilate harmful substances away from the worker. They can also help to contain potentially explosive or volatile substances, which ultimately prevent accidents.

Fume Hood Used For

Lab fume hood allow employees to work with chemicals, biological agents, or radioactive materials without any dangerous effects. These hoods offer protection by capturing and exhausting harmful substances, either outside the building through a system or through air filtration back into the room. Therefore, the lab environment remains free of toxic exposure and people can work there with peace of mind.

Here are some more uses of fume hoods.

- Semiconductor manufacturing: People widely use fumes to safely handle, toxic chemicals involved in the production and processing of semiconductors.

- Aerospace surface finishing: In industries like Aerospace, surface treatments like passivation involve the use of nitric acid and other hazardous chemicals. This is why, hues are helpful in such treatments to lower toxicity.

- Research laboratories: Academic and industrial research labs of colleges and universities use fume hoods during experiments.

- Cross-contamination: Contamination occurs in some sensitive experiments. One can use fume hoods to control airflow and prevent particles or substances from spreading in such experiments.

Fume Hood Function

The main function of fume hood is to protect laboratory workers from exposure to extremely harmful vapor, smoke, or dust during chemical experiments. It works by trapping airborne contaminants inside the wood and safely wind them away from the work area. The fume extraction hood creates a controlled environment with the help of a ventilation system. The system draws in air and exhausts harmful substances through filters and ducks. This system ensures that workers stay safe from inhaling, dangerous chemicals. Therefore, no accident can happen.

Benefit of Fume Hood

A fume hood offers several benefits in a laboratory or workspace environment:

Safety

The primary benefit of a fume hood is the protection it provides to workers and the surrounding environment. It effectively contains and removes hazardous fumes, gases, and particles.

Health Protection

By effectively removing harmful substances from the air, a fume hood helps safeguard the health of laboratory personnel. It reduces the potential for respiratory issues and other health problems.

Chemical Spill Containment

In case of accidental chemical spills or splashes, a fume hood acts as a containment system. It prevents the spread of hazardous substances and minimizes the risk of contamination in the laboratory.

Versatility

Fume hoods are designed to accommodate various laboratory procedures and experiments. They provide a flexible workspace where different types of chemical manipulations can be carried out safely.

Regulatory Compliance

Fume hoods play a crucial role in meeting regulatory requirements and industry standards for laboratory safety. By utilizing a fume hood, organizations can ensure compliance with regulations.

Increased Productivity

With the assurance of safety and proper ventilation, researchers and laboratory personnel can focus on their work without the constant concern of exposure to hazardous substances.

Fume Hood Safety Precautions

Fume hood is very important for laboratory safety, but they must be used properly to be effective. Here are some safety precautions that all labs should follow.

- It is important to keep the sash at the recommended height to ensure proper airflow.

- One must avoid blocking the airflow slots as this can disrupt ventilation.

- You should not store chemicals inside the food

- Always check that the food is running before starting work.

- Do not forget to perform regular checks to ensure the ventilation system is functioning correctly.

- You should avoid leaning inside the food when in use.

- Keep the work area clean and dispose of chemicals safely.

Types of Fume Hoods

There are various types of fume hoods available, each designed to cater to specific laboratory requirements. Here are a few common types:

- Ducted Fume Hood: This is the most common type of fume hood, which uses an exhaust system connected to a duct network to expel contaminated air outside the building. It is suitable for handling a wide range of hazardous substances.

- Ductless Fume Hood: Unlike ducted fume hoods, ductless fume hoods do not require an exhaust system. Instead, they use filtration systems to remove and neutralize contaminants from the air before recirculating it back into the laboratory. They are often used in situations where ducting is not feasible or when flexibility in laboratory layout is required.

- Walk-In Fume Hood: Walk-in fume hoods are large enough for personnel to enter and work inside. They are used for processes that involve bulky equipment or handling large quantities of hazardous materials. These hoods provide ample space, visibility, and enhanced accessibility.

- Benchtop Fume Hood: Also known as a tabletop fume hood, this type is compact and sits on a laboratory bench or countertop. It is suitable for smaller-scale experiments or procedures that require localized containment of hazardous substances.

- Auxiliary Fume Hood: Auxiliary fume hoods are specialized hoods that are used in conjunction with larger fume hoods or ventilation systems to provide additional containment and safety measures. They are typically used for handling highly toxic or volatile substances.

- Perchloric Acid Fume Hood: Perchloric acid fume hoods are specifically designed to handle experiments involving perchloric acid, which is highly reactive and requires special containment measures. These hoods have additional safeguards to prevent the buildup of explosive perchlorate salts.

Fume Hood Ventilation Requirements

Fume hoods rely on an exhaust blower to pull air through the hood and exhaust system. The airflow is measured by multiplying the sash opening area by the desired face velocity. For example, a 7.5 square foot sash opening with 100 feet per minute face velocity results in 750 CFM. For variable air volume (VAV) hoods, the airflow adjusts based on sash movement. Proper airflow is essential to maintain negative pressure in the lab and prevent contaminants from escaping. Too much or too little airflow can cause safety issues. Lab airflow should be free of turbulence to ensure contaminants are effectively removed. The airflow should also be smooth and free of turbulence to ensure contaminants are efficiently drawn into the hood. This can be affected by nearby airflow vents or excessive movement around the hood. Any equipment inside the fume hood must be placed at least six inches behind the airfoil, and the baffle area should remain clear to allow proper airflow. It’s also essential to limit heat sources inside the hood to maintain effective operation.

Fume Hood Specifications

| Type of Fume Hood | Overall dimension | Inner dimension | Worktop height | ||||

|---|---|---|---|---|---|---|---|

| L | W | H | L1 | W1 | H1 | H0 | |

| Bench Type Fume Hood | 1200 | 915 | 2300 | 1000 | 645 | 1250 | 900 |

| 1500 | 915 | 2300 | 1300 | 645 | 1250 | 900 | |

| 1800 | 915 | 2300 | 1600 | 645 | 1250 | 900 | |

| 2100 | 915 | 2300 | 1900 | 645 | 1250 | 900 | |

| 2400 | 915 | 2300 | 2200 | 645 | 1250 | 900 | |

Fume Hood Maintenance Checklist

One should focus on the regular maintenance of fume hoods to ensure they work efficiency. You must check the session regularly to ensure it opens and closes smoothly. The sash should be set at the correct height. It is also important to test airflow to ensure the proper ventilation rate. (89-120 fpm). Additionally, inspect the ventilation system for any blockages or leaks. The interior of the wood should be clean to prevent the buildup of chemicals or debris. Moreover, one must check the exhaust system to ensure it is free from obstruction. Needless to mention, filters must be replaced in recirculating hoods as needed. Besides, all the safety features of the hood like alarms or warning lights must be in good working condition.

Contact Fume Hood Manufacturers

Labswas is considered as the top Fume Hood manufactures and suppliers in UAE. We have our own ultra modern manufacturing plant is situated in Ahmedabad, India. We provide wide range of fume hoods at market leading prices. Clients can also request for custom cleanroom equipment as we also manufacture equipment as per given specifications. Our equipment provide excellent output and need minimum maintenance. Moreover, our support team is always ready to provide best assistance to clients. You can get premium quality fume hood at market leading price with us.