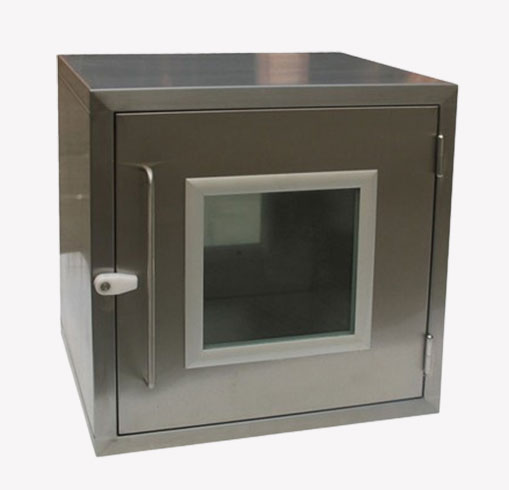

Pass Box

Pass Box Manufacturers

Labswas is counted as the leading Pass Box manufacturers and supplier in UAE, Dubai. We offer wide range of cleanroom equipment and pass boxes such as Static Pass Box and Dynamic Pass Box. Our pass through box is made using premium quality materials in our modern manufacturing unit. These are quality tested on various parameters for their durability, output and excellent performance. Our manufacturing facility is equipped with ultra modern machineries and we contain all the required international norms and certifications. Our pass box clean room is widely used in Laboratories, R&D sector, Hospitals, Food industry, Electronics, Clinics, Chemicals and many more.

Feel free to get in touch!

info@labswas.com

+91 97262 18377

Feel free to get in touch!

info@labswas.com

+91 97262 18377

What is a Pass Box?

Pass boxes are quite common in clean rooms. A pass box is a small and sealed piece of equipment that allows people to transfer materials from one area to another in a controlled way. One can see a possible box located in between the partition walls of cleanrooms. They are also called transfer hatches or SAS(sterile access system) passes. There are some non-viable particles in microorganisms, that can cause contamination if they enter the clean room. This is why the entry and exit of materials should be done in controlled environments with no contamination exposure. A pass box is the best solution as it creates a barrier between the clean rooms. It maintains a sterile environment by preventing the exchange of air between two spaces. Moreover, it has two doors. When one door is opened, the other door automatically closes itself. This type of interlocked door prevents air and contaminants from entering the clean area. Note that some pass boxes come with UV lights which stabilise the area. Therefore, it controls bacteria. The pass through box not only prevents airflow disturbance but also reduces the time of operators required for moving in and moving out. Hence, no dust can come in from outside. the passes are divided into two types based on the purpose they serve. They are static pass boxes and dynamic pass boxes. Both are important for different sectors.

Pass Box Applications

Pass box is important equipment in industries where cleanliness and hygiene are the utmost priority. A transfer hatch is beneficial in clean rooms as it allows workers to send or receive supplies without opening the main clean room door. Thus, it prevents contaminants. Additionally, a transfer hatch is used in the pharmaceutical industry while making medicines under hygiene standards. Pass boxes also help to transfer medical supplies between clean and non-sterile areas in hospitals to minimize contamination. Recently, the electronics industry has been also seen employing pass boxes to transfer sensitive components between areas like assembly and testing. These types of equipment allow manufacturers to prevent dust and contaminants from harming delicate electronic parts. Moreover, a pass box clean room facilitates the safe transfer of food ingredients in food and beverage production facilities. These types of equipment allow manufacturers to prevent dust and contaminants from harming delicate electronic parts. These boxes help in transferring biological samples and energy agents between controlled classrooms in biotechnology labs. One can use this to transfer aircraft components in case of aerospace industry. Besides, the cosmetic industry uses pass boxes to transfer raw materials and finished products while adhering to strict hygiene standards.

Pass Box Requirement

The pharmaceutical industry requires a pass box to comply with class B cleanliness standards. It means that the box should be using high-efficiency filters like HEPA or ULPA. This is because these powerful filters can trap 0.3 µm particles. Additionally, a box should be equipped with interlocking door systems so that both doors do not open at the same time. The UV lamp is also an important component to check as it activates and disinfects materials during the transfer process. The pass through box has rounded corners internally so that there are no hard-to-reach areas. The system should operate at low noise levels. Moreover, there should be proper systems in the past to monitor pressure differentials. Hence, it indicates whether filters need replacement or maintenance. Pass boxes are made from stainless steel due to its durability and ease of cleaning. Stainless steel is mainly preferred due to its durability, corrosion resistance, and ease of sanitation. Note that the internal surfaces must be smooth and without any corners or gaps that could trap dust or debris. The outlet air velocity after passing through HEPA filters should be controlled within a specified range (e.g., 0.38-0.57 m/s) to maintain optimal airflow conditions. Another critical requirement is the size of the pass box. It should be large enough to accommodate the materials or equipment being transferred without difficulty. However, it should not be too large, as this could lead to unnecessary air disturbance. some models come with adjustable shelves or racks to accommodate different items. This indeed improves their versatility. There are certain industries like pharmaceuticals, food processing, and healthcare, where pass boxes need to meet certain regulatory requirements set by governing bodies.

Contact Pass Box Manufacturers

Known as one of the top Pass Box manufacturers in UAE, Dubai, we offer only the best pass box clean room. We make them available in various shapes, sizes and specifications as per customer requirement. We also offer custom product solutions for various application requirements. Our quality experts perform various tests to ensure that you will get perfect pass box to fulfill your requirement. Moreover, our support team is always ready to assist you with any query of our cleanroom equipment. You will get the best product solution at market leading prices with us.